Custom Manufacturing: Expectations vs Reality

After years of decline and overall slow growth, the manufacturing sector is starting to thrive once again. No doubt aided by technological growth and innovation, the uptick should largely be seen as a positive thing.

On the flip side, however, there are still major challenges to be faced.

In this article, we take a look at what these challenges are – and we also present some solutions.

Shortage of Labor

Baby boomers acquired lots of skills that were valuable to the manufacturing sector. In 2019, however, many are exiting the workforce and taking those skills with them. As a result, the worry is that they’ll leave behind 2.4 million unfulfilled jobs.

The rise of Artificial Intelligence, robots and automation are helping to plug the gap, but only to a certain extent. A labor shortage is real, with the lack of trade school opportunities for young people being a growing problem.

A solution lies with solid training programs aimed at teaching candidates the right skills needed to thrive in the manufacturing sector. These skills include sheet rolling, robotics programming, and welding.

Manufacturers also need to improve the way they attract workers, and this means employing extensive digital marketing strategies and utilizing social media.

Keeping Up To Date With The Latest Technologies

Cloud computing, robotics, artificial intelligence and the Industrial Internet of Things are just some examples of advanced technology that is helping the custom manufacturing sector.

The problem is that many manufacturers are struggling to keep abreast of all the latest changes and advances. Worse still, technologies are developing at such a fast pace that once manufacturers have got to grips with a piece of technology, a new one is developed.

It’s a smart idea for businesses to work closely with consulting firms who have experience with manufacturing, and the latest technologies. This will allow the business to make faster strides forward, and it will give them the insights and assistance needed to adapt as fast as – if not faster – than their rivals.

This is key because, as analyst firm IDC points out, spending on drones and robotic systems is expected to eclipse $115 billion by the end of 2019.

Other technologies manufacturers need to get to grips with include blockchain, which will soon directly impact the cost-effectiveness, security, and speed of financial transactions and operations in the manufacturing sector.

3D printing is another piece of technology that is continuing to evolve and improve. Its ultimate benefit will be cheaper, stronger and better manufacturing.

Cybersecurity

So, technology is rapidly evolving. While this is clearly beneficial to the manufacturing sector, there is a darker side. Namely, those cybercriminals are upping their game at the same time.

Cryptominer’s and banking Trojans have been named as the two biggest cybersecurity threats that the manufacturing industry is now facing. The concern is that too many manufacturers are still using old and outdated security systems that are simply unable to thwart these attacks.

Businesses need to start employing better, more sophisticated and advanced ways of keeping their networks strong and secure. The traditional firewall approach that worked in the past is no longer enough.

To that end, it’s a good idea to make sure all your computer security software is updated frequently. Educate your staff about the telltale warning signs, too.

Fierce Global Competition

The U.S. has traditionally been the world’s most competitive economy – but all that has now changed. China is now leading the way, although the U.S. is still in hot pursuit.

To get back on track, attracting the best talent and getting to grips with the most sophisticated and up-to-date technologies are essential. Production will need to be shifted to a higher value, too, while offering new service-based pricing models and product-as-a-service are seen as other ways to keep the manufacturing sector competitive.

Attracting The Right Leads

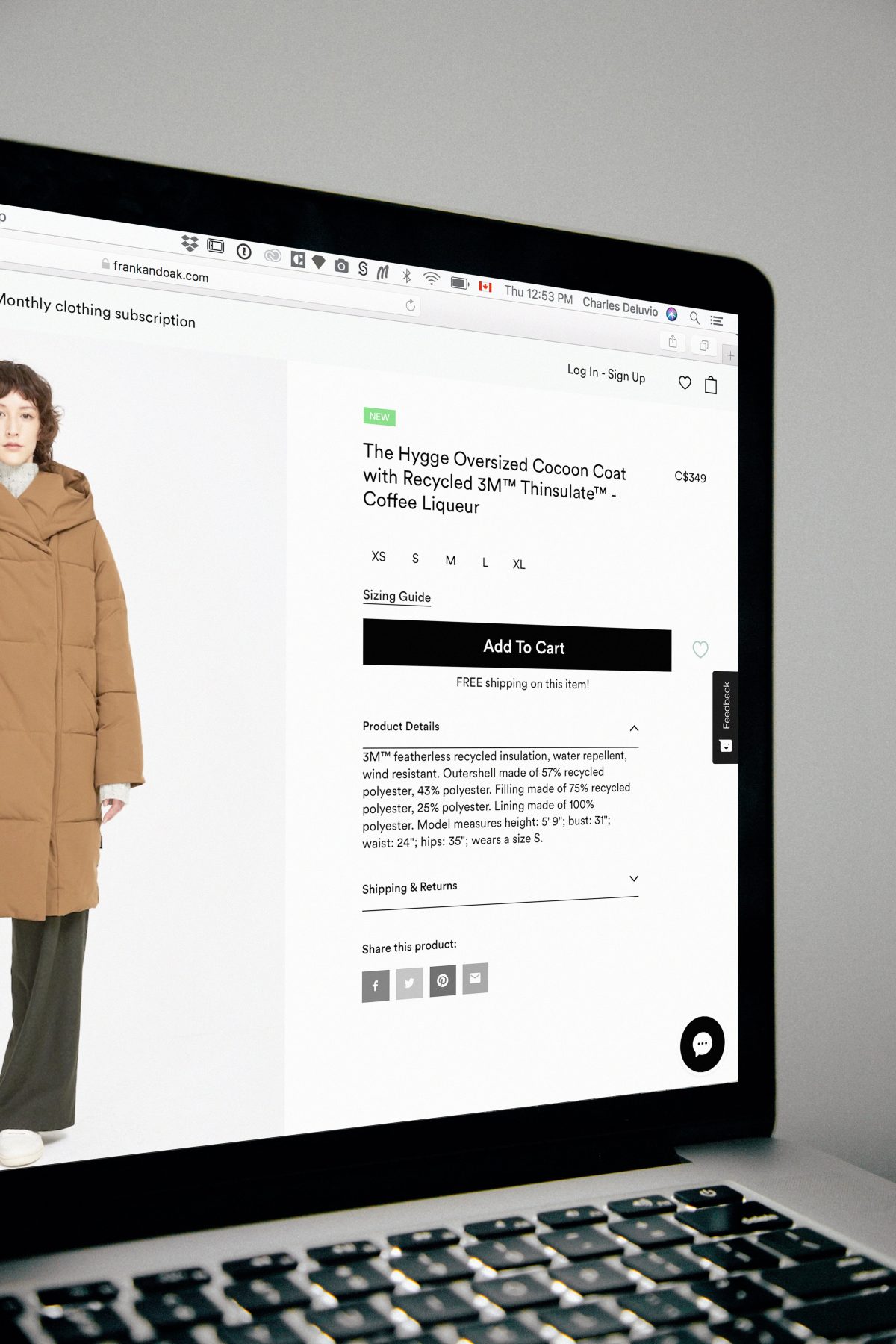

In the past, manufacturers would rely on ‘old school’ ways of attracting leads – cold calls, trade shows and the like. In 2019, that won’t cut it anymore.

Manufacturers need to invest heavily in a robust digital marketing strategy. While building a website is important, what’s more, important is that manufacturers take care of the many facets of digital marketing to increase leads. This means creating content marketing campaigns, SEO campaigns, email marketing campaigns, and even social media campaigns.

Digital marketing is all about building relationships and connecting with people where they are at. It also means creating lots of value and giving things away for free that educates their audiences, such as eBooks, case studies and infographics.

Conclusion

Whatever kind of manufacturing industry you’re involved in, it’s really important that you’re aware of the expectations and the realities.

Custom manufacturing is heading in the right direction, and it’s really important that your business follows the latest trends. Use the tips in this article to get up-to-date with where custom manufacturing is, and then put into place plans of action that generates better results in our ever-evolving world.

CRM (

CRM (

Content marketing can be basically defined as one of the most strategic approaches for marketing which is specifically focused on the creation and the distribution of several valuable, reliable, relevant contents in a consistent manner in order to attract some clear audiences and also to retain them so that the customer action can become more profitable for the business. Compared to the traditional methods of marketing in which the companies would only thrust the products and brands they had to consumers, the content marketing is basically dependent on the techniques of inbound and pull marketing in which the companies would be offering you more relevant, beneficial and also insightful information to the audience and that too for no extra cost.

Content marketing can be basically defined as one of the most strategic approaches for marketing which is specifically focused on the creation and the distribution of several valuable, reliable, relevant contents in a consistent manner in order to attract some clear audiences and also to retain them so that the customer action can become more profitable for the business. Compared to the traditional methods of marketing in which the companies would only thrust the products and brands they had to consumers, the content marketing is basically dependent on the techniques of inbound and pull marketing in which the companies would be offering you more relevant, beneficial and also insightful information to the audience and that too for no extra cost. Also Read:

Also Read:  Humans are visual creatures and don’t think that how your website looks don’t matter. The presentation of a website is an important part of UX design, one that shouldn’t be neglected. Keep in mind that your website is a means of communication between yourself and your potential clients. Why not make this channel as pleasing as possible?

Humans are visual creatures and don’t think that how your website looks don’t matter. The presentation of a website is an important part of UX design, one that shouldn’t be neglected. Keep in mind that your website is a means of communication between yourself and your potential clients. Why not make this channel as pleasing as possible?  Annoyance is perhaps a bit crude of a term, but it’s perfect to describe what you don’t want your visitors to feel when they visit your website. Namely, think of the things that would annoy you if you were to visit a certain website. Then, think about whether any such elements are present in your own thing. For example, we already mentioned how short our attention spans are. But, your content matters here as well. Sales language, too many calls to action, just forcing your user to do things in general, all of these things are not going to be received warmly. Try not to sound like an aging used-car salesman as well. Present people with clear, actual facts about your services and products.

Annoyance is perhaps a bit crude of a term, but it’s perfect to describe what you don’t want your visitors to feel when they visit your website. Namely, think of the things that would annoy you if you were to visit a certain website. Then, think about whether any such elements are present in your own thing. For example, we already mentioned how short our attention spans are. But, your content matters here as well. Sales language, too many calls to action, just forcing your user to do things in general, all of these things are not going to be received warmly. Try not to sound like an aging used-car salesman as well. Present people with clear, actual facts about your services and products.